- SPICE Training Catalog

intacs Certified Provisional Assessor (Automotive SPICE® v3.1)

intacs Certified Competent Assessor (Automotive SPICE® v3.1)

Introduction to the VDA Automotive SPICE® Guidelines

intacs Training: Automotive SPICE® for Cybersecurity

- Info2023-06-21Published by Achim Gerber on 2023-06-21Categories

- About Us

- My account

简体中文

简体中文

Why Automotive SPICE

What is Automotive SPICE?

2023-05-09

Bach's bakery is serving a growing clientele in Changsha with a team of hearing-impaired workers. Customers love the shop. They can get every day the same high quality of products.

Bach's bakery is serving a growing clientele in Changsha with a team of hearing-impaired workers. Customers love the shop. They can get every day the same high quality of products.

Once the owner told me, he rather pays more for the ingredients with ongoing high quality, than adapt the recipe and procedures for every purchase.

They have an excellent team spirit going. Everybody knows the steps and their particular role. They have successfully overcome the challenge of communication.

No wonder they won an award with their bakery!

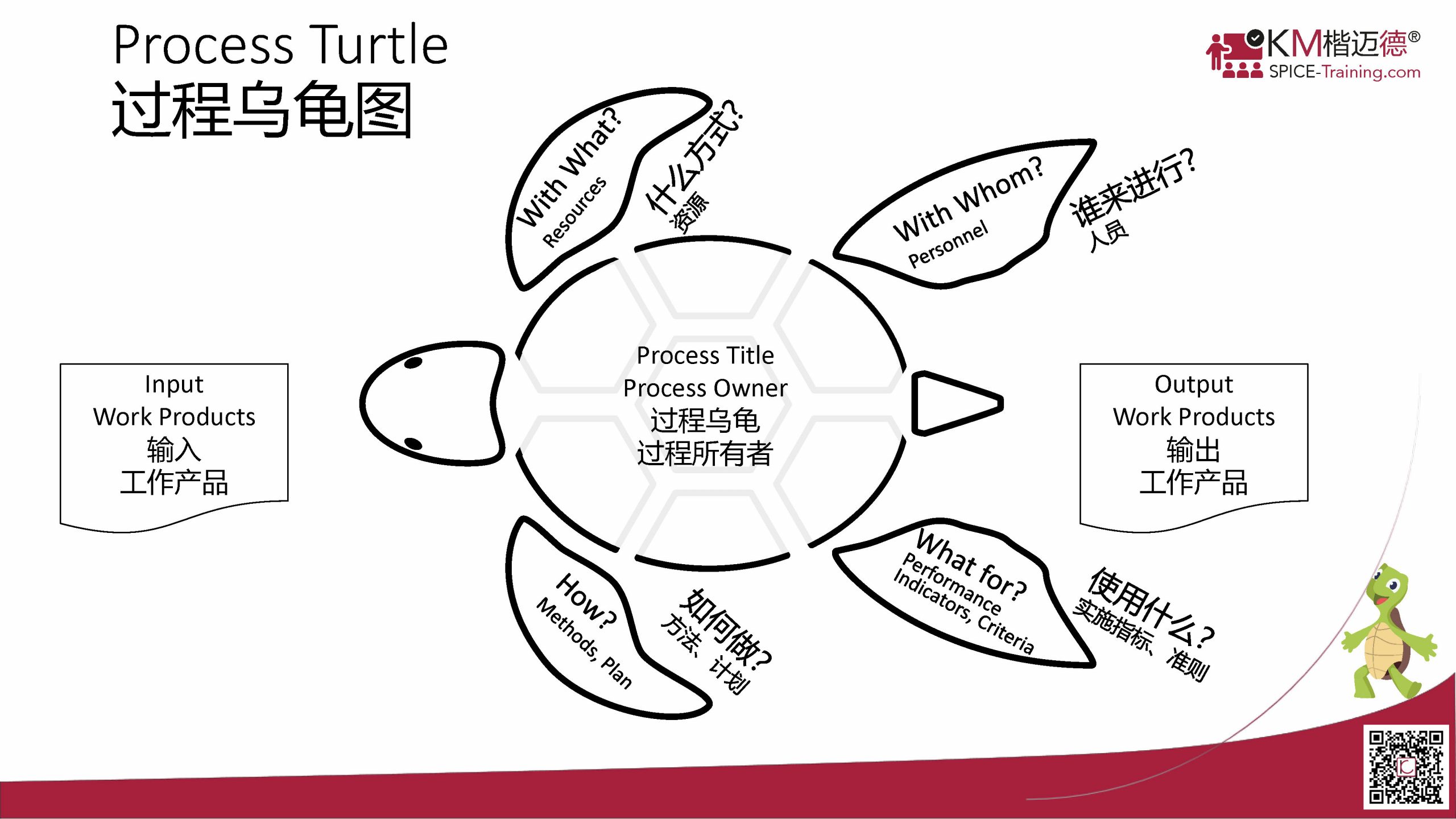

The Process Turtle

The Process Turtle

Baking bread is an example of a typical process. The process turtle above is often used to illustrate what a process is.

We have learned good output work products come from good input work products.

Customers coming in the morning for breakfast want their baked goods ready. The objective is clear. All the activities are planned, performed, and if needed to be adjusted, in order to be ready when the shop opens for customer traffic.

Carmakers (OEMs) want continuous high quality in their deliveries

Software-driven systems will soon be 50% of the value of the car. The expectation is clear: The integrated system of hardware, software, and electromechanical components need to be fully qualified with respect to the requirements. The output of the engineering processes is a system that was developed with compliance to Functional Safety (ISO 26262) and Cybersecurity (ISO 21434) and all other stakeholders.

The OEM can validate some of the functionality. But for most aspects of the delivery, they need to trust test results and other documents included in the delivery.

Are there unknown bugs? Are all risks identified and communicated?

In other words, the product is only as good as the development processes.

SPICE - Software/System Process Improvement and Capability Determination

SPICE - Software/System Process Improvement and Capability Determination

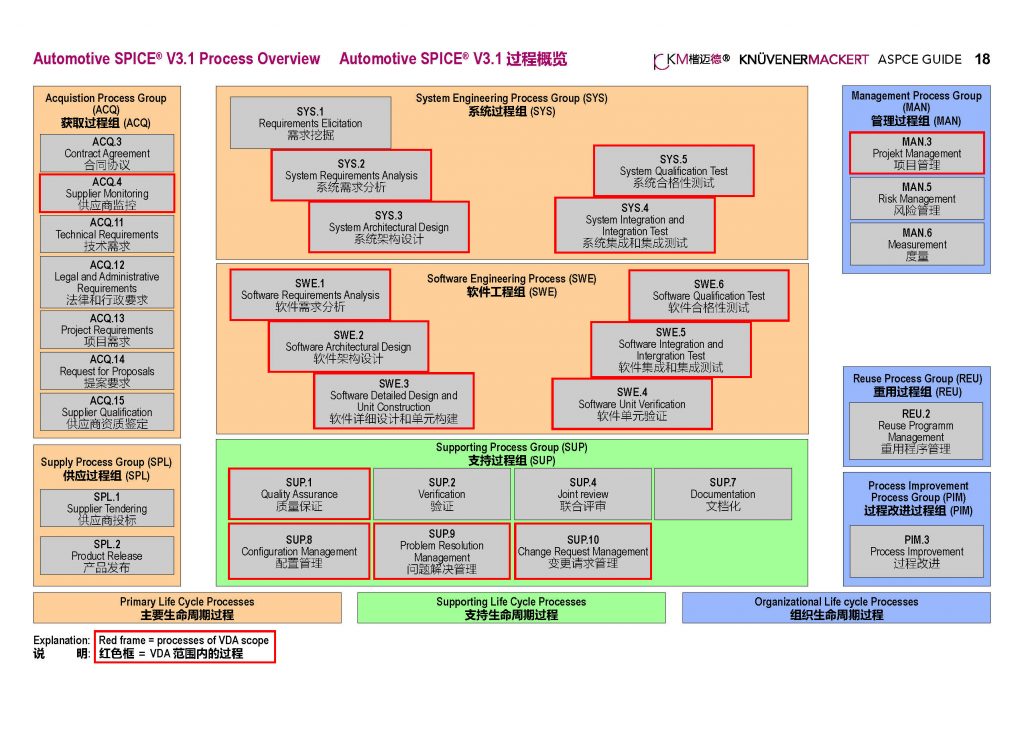

The processes with the red frame belong to the standard set of 16 processes of the VDA Scope. In the process assessment model (PAM) every process has to fulfill a clear purpose and operates according to defined base practices. The capability level CL2 introduces general practices for the management of the process and work products. CL3 then describes criteria for how standard processes need to be defined and how it is deployed to new projects.

Automotive SPICE is a PAM according to ISO 33020 that is used by the development team to improve the processes to the standard reflected in the industry's best practices.

The flow of Assessments is defined in ISO33002. A lead assessor with a team of co-assessors performs interviews and rates the processes of a project in respect to Automotive SPICE as an assessment model.

The rated capability gives then an indication of the quality of the project's output - the qualified delivered system.

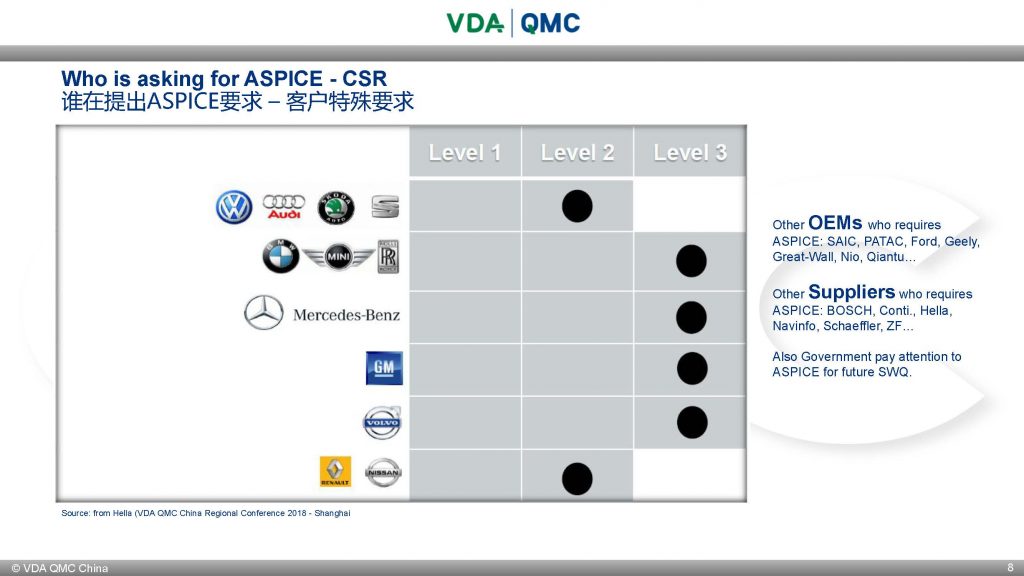

Why Automotive SPICE?

The answer becomes clear. Software-driven systems are so complex, that without a defined process structure, the unknown risks and bugs in the system become a liability the OEMs need to eliminate.

The figure above shows that many OEMs request Automotive SPICE (ASPICE) from their suppliers. It is general practice, that even suppliers long time in the business will not get follow up contracts if their project does not reach capability level 2 or even level 3.